Introduction to Power Transmission Efficiency

Power transmission efficiency plays a crucial role in modern industrial applications. By optimizing power transmission systems, businesses can significantly reduce energy costs and enhance system performance. Understanding the balance between input and output energy within these systems is essential for maximizing productivity.

Why Power Transmission Efficiency Matters

The importance of power transmission efficiency cannot be overstated. It ensures that minimal energy is wasted during the transfer from point A to point B, thus improving overall system effectiveness. Enhanced energy efficiency translates directly to lower operational costs, making your business more competitive.

Investing energy into improving power transmission system efficiency also minimizes downtime, which in turn boosts productivity levels. Enhanced systems have fewer breakdowns and require less frequent maintenance, contributing to long-term cost efficiency.

Moreover, efficient systems are typically more robust, supporting greater resilience against mechanical failures and improving equipment reliability over time. As a result, industries that prioritize these practices often see a reduction in the need for associated repairs and maintenance expenses, emphasizing the importance of preventing equipment failure prevention.

Impact on Energy Costs

Energy efficiency in power transmission directly impacts operational budgets. By ensuring that systems operate at optimal efficiency, companies can significantly slash their energy bills. Even small improvements in efficiency can yield substantial savings, considering the large-scale applications involved.

Additionally, by reducing the energy consumption index, businesses positively affect their carbon footprint. With global industries prioritizing environmental concerns more than ever, improving energy efficiency can enhance a company’s sustainability profile.

System Performance Improvements

Enhancing power transmission efficiency equals improved system performance. Systems with high efficiency operate smoothly, with less wear and tear on components such as bearings. This not only extends component lifespan but also boosts the machinery’s overall reliability. Therefore, focusing on system efficiency is not just a maintenance decision but a strategic operational enhancement.

Implementing advanced monitoring technologies can further optimize performance. Such tools can provide real-time insights into system operations, helping identify potential issues before they develop into significant problems, enhancing predictive maintenance capabilities.

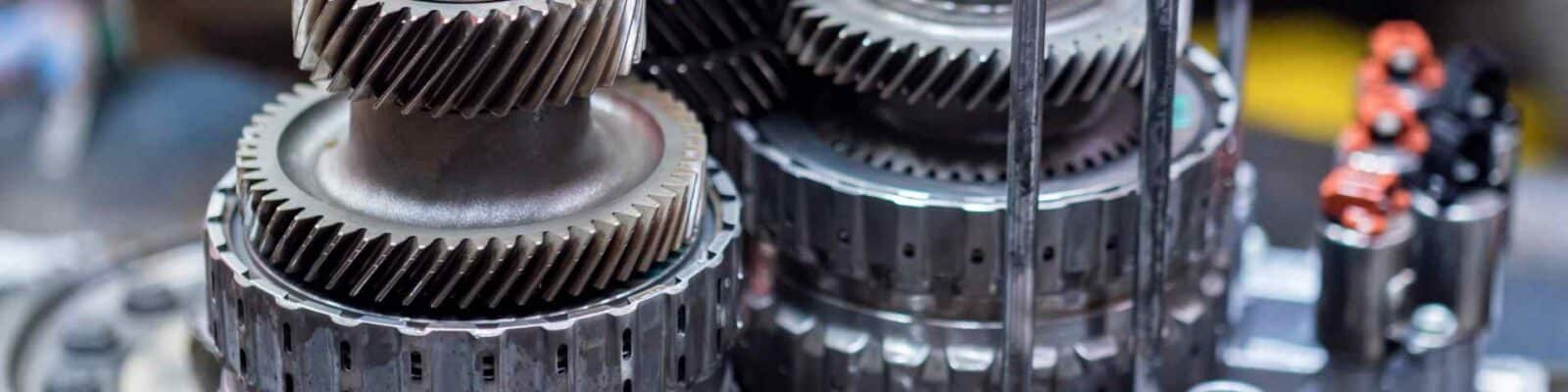

Internal gears and parts of a mechanical power transmission system, emphasizing efficiency.

Understanding Power Transmission Systems

Power transmission systems consist of numerous components that work in tandem to ensure effective energy transfer. Each element, from gears to v-belts and pulleys, plays a pivotal role in determining the overall efficiency and reliability of the system.

Transmission System Components

The components of a power transmission system include a variety of mechanical parts such as shafts, bearings, and couplings. Each component is integral to the machinery’s ability to transfer power effectively. For instance, bearings cushion and support rotating shafts, while couplings connect different equipment sections and facilitate seamless power transfer.

Understanding each component’s role can help in maintaining the system efficiently. Regular checks and timely servicing of these parts ensure that the system remains operational and cost-effective over time.

Role in System Efficiency

Each component’s condition directly influences the system’s efficiency. Malfunctioning components may lead to increased friction and energy loss. Therefore, it’s essential to keep each part in top condition to facilitate smooth operations.

Regular component audits and timely replacement of worn-out parts are essential practices. It’s also crucial to ensure that components such as bearings are suitable for their specific applications, a principle explored in choosing the right bearing.

Maximizing Component Performance

Optimal performance of components involves regular lubrication, precise alignment, and monitoring of system conditions. Implementing maintenance programs tailored to the specific needs of each component enriches their longevity and efficiency.

Advanced condition monitoring tools can aid in predicting when a component might fail, allowing for preemptive maintenance actions. This proactive approach not only saves costs but also minimizes unexpected downtime, enhancing overall operational efficiency.

Strategies to Enhance Power Transmission Efficiency

Enhancing the efficiency of power transmission systems involves adopting new strategies and technologies that streamline energy usage and improve system reliability. Embracing innovative solutions can lead to significant advancements in machinery performance.

Innovative Technologies

Adopting cutting-edge technology is pivotal for improving power transmission efficiency. Technologies such as variable frequency drives and smart sensors enable more dynamic control over machinery, optimizing energy use and reducing wastage.

These technologies not only provide operational benefits but also extend the life of components by preventing overloads and systematic wear. By integrating such innovations, a company can significantly boost equipment reliability and operational success.

Implementing technologies that automatically adjust machine operations based on load demands saves energy and increases efficiency. The integration of these technologies marks a strategic move towards modernized industrial applications.

Energy-Efficient Practices

Implementing energy-efficient practices is fundamental to reducing energy consumption in power transmission systems. Practices such as ensuring proper lubrication, maintaining optimal temperature, and regular alignment checks are essential for operational excellence.

Employing a systematic approach to energy management can lead to substantial cost savings. Businesses are encouraged to regularly evaluate their consumption patterns and make incremental adjustments that support energy-efficient operation.

Modernizing Existing Systems

Modernizing current systems is a cost-effective strategy for enhancing power transmission efficiency. Retrofitting machines with state-of-the-art components can bridge the gap between outdated infrastructure and modern efficiency standards.

Identifying and replacing legacy components with energy-efficient alternatives ensures continued alignment with industry best practices. Such actions contribute to a comprehensive strategy that enhances both system longevity and performance.

Moreover, by integrating equipment management systems that monitor performance metrics, businesses can tailor maintenance and operational practices to maximize efficiency across their industrial facilities.

Detailed view of power transmission components, crucial for mechanical operations in industry.

Ensuring Longevity through Maintenance

Proper maintenance practices are critical to the efficient functioning and longevity of power transmission systems. Routine maintenance not only helps avoid unexpected failures but also increases machinery lifespan significantly.

Benefits of Routine Maintenance

Regular maintenance activities contribute significantly to system efficiency. These scheduled tasks help identify potential problems before they develop into costly failures. They also help in maintaining steady system performance, thus improving the equipment’s reliability and operational lifespan.

Routine checks reduce the likelihood of catastrophic failures, ensuring equipment runs smoothly and efficiently. By adopting comprehensive maintenance schedules, businesses can save significantly on repair costs, reinforcing the value of industrial equipment maintenance.

Best Maintenance Practices

Effective maintenance practices are essential for sustaining power transmission system efficiency. These include:

- Regular Inspections: Frequent system audits to identify wear and tear.

- Component Lubrication: Ensures smooth operation and reduces friction.

- Alignment Checks: Prevents imbalances that could cause breakdowns.

- Monitoring System Conditions: Utilizing tools to track performance metrics.

- Scheduled Overhauls: Comprehensive checks conducted periodically.

- Replacement of Worn Parts: Timely upgrade of outdated components.

- Cleaning and Upkeep: Regular removal of dust and debris to ensure efficiency.

- Record Keeping: Documenting maintenance actions for future reference.

Applying these practices ensures machinery performance remains top-notch while minimizing the risk of accidents, promoting material handling safety.

Using Predictive Maintenance Tools

Predictive maintenance tools have revolutionized traditional maintenance strategies. By utilizing technologies like sensors and data analytics, companies can predict failures before they occur, enhancing reliability.

This proactive approach not only reduces downtime but also extends the equipment’s usable life by preventing excessive wear and tear. The use of these tools aids in making informed decisions regarding maintenance schedules and establishing long-term maintenance strategies.

Significance of Preventive Maintenance

Preventive maintenance plays a crucial role in reducing downtimes and enhancing power transmission efficiency. By adopting a proactive approach, businesses can ensure seamless operations and extend equipment lifespan.

What is Preventive Maintenance?

Preventive maintenance involves regular, planned activities designed to prevent equipment failures before they occur. This approach focuses on routine inspections and maintenance, which address potential issues early, significantly reducing the risk of unplanned downtimes.

By maintaining a regular maintenance schedule, companies can ensure components are well-maintained and operational, thus boosting both productivity and efficiency. Preventive maintenance also assures that systems operate safely and consistently.

Preventive vs. Reactive Approaches

Preventive and reactive maintenance have distinct contrasts. Reactive maintenance involves fixing issues post-failure, often resulting in costly downtimes and repairs. In contrast, preventive maintenance offers a more efficient and cost-saving approach by addressing problems before they escalate.

The proactive nature of preventive maintenance ensures less disruption to daily operations, facilitating smoother industrial processes. By adopting preventive approaches, businesses can effectively manage unexpected outages, promoting greater operational reliability.

Steps to Implement Preventive Maintenance

Implementing an effective preventive maintenance strategy involves the following steps:

- Evaluate Current Practices: Assess existing maintenance routines and identify areas for improvement.

- Develop Maintenance Schedule: Create a structured plan detailing regular service intervals.

- Train Staff Effectively: Ensure maintenance teams are well-trained in system operations and repair techniques.

- Use Technology for Monitoring: Employ sensors and analytics for real-time data collection.

- Analyze Data for Improvements: Utilize performance data to optimize maintenance strategies.

- Cost-Benefit Analysis: Evaluate the financial impact versus the benefits of maintenance activities.

- Continuous Improvement: Regularly update practices based on new insights and technologies.

Following these steps ensures a comprehensive and effective maintenance strategy that not only enhances operational efficiency but also significantly extends system lifespan by effectively adopting preventive maintenance.

Close-up of interconnected power transmission gears and drives in an industrial setting.

Maintenance Tools for Power Transmission Systems

Utilizing the right tools and equipment is essential for effective maintenance of power transmission systems. Proper tools ensure efficient maintenance procedures, contributing to increased equipment reliability and reduced downtime.

Essential Maintenance Tools

Basic maintenance tools are crucial for routine inspections and minor repairs. Such tools include wrenches, screwdrivers, pliers, and hammers, which are essential for managing adjustments and component replacements.

Ensuring the availability of these essential tools can expedite maintenance tasks, ensuring quick resolutions for minor issues. It’s critical to keep tools in good condition, as reliable tools are necessary for performing accurate maintenance tasks over time.

Advanced Monitoring Equipment

Advanced monitoring equipment such as thermal sensors, vibration analyzers, and ultrasonic flaw detectors have transformed maintenance capabilities. These tools provide critical insights into system conditions, revealing information that might not be apparent during visual inspections.

By adopting these technologies, companies can proactively address issues and optimize maintenance routines, ensuring better operational efficiency and facilitating downtime reduction.

Selecting the Right Tools

Selecting appropriate tools requires careful consideration of the system’s specific maintenance requirements. Both basic and advanced tools should be selected based on the machinery’s design and usage level, ensuring comprehensive maintenance capacity.

Decision-makers should also consider the equipment’s compatibility with specific tools for effective task execution. By tailoring tool selection to the system’s unique needs, maintenance operations can be more efficient, thereby bolstering operational efficiency.

Challenges & Solutions in Maintenance

While maintaining power transmission systems is crucial, it comes with its own set of challenges. Addressing these efficiently requires strategic planning and innovative problem-solving abilities.

Common Maintenance Challenges

Organizations often encounter common challenges during maintenance, including:

- Component Wear and Tear: Regular use leads to inevitable deterioration.

- Inefficient Lubrication: Insufficient lubrication can cause component damage and system inefficiency.

- Operator Error: Human mistakes during maintenance can lead to unintended consequences.

- Environmental Factors: External conditions like temperature and humidity can affect systems.

- Aging Equipment: Older machinery often requires more frequent maintenance.

- Supply Chain Issues: Delays in parts supply can impact repair schedules.

- Budget Constraints: Limited resources may restrict maintenance activities.

- Training Needs: Skill gaps in teams can hinder effective maintenance.

Troubleshooting Tips

To effectively manage these challenges, organizations must employ comprehensive troubleshooting techniques. This includes the use of systematic diagnostic procedures to quickly identify and resolve issues, thereby decreasing downtime.

Leveraging a detailed troubleshooting guide can also facilitate faster problem resolution. Emphasizing analytical skills alongside technical knowledge helps maintenance teams address complex issues with precision, such as belt drive troubleshooting.

Proactive Measures

Proactive maintenance measures significantly reduce the chance of unexpected breakdowns. Implementing measures such as periodic system audits and staff training ensures that maintenance teams are prepared for any situation.

Collaboration across departments regarding maintenance activities leads to optimized resource allocation and efficient operational practices. By maintaining thorough communication, businesses can stay ahead in maintenance capabilities while improving lockout tagout (LOTO) processes.

Choosing the Right Power Transmission Systems

Choosing the appropriate power transmission system is crucial for ensuring both efficiency and reliability. Comprehensive evaluation of available components and system configurations is necessary for making smart investment decisions.

Criteria for Selection

Selecting the right system involves understanding the specific operational requirements and constraints. Key criteria include load capacity, speed requirements, and environmental conditions affecting system operation.

Careful consideration of these criteria ensures the system selected fulfills all operational requirements. Decision-makers need to thoroughly analyze available options to align with business objectives.

Comparing Different Types

There are various types of power transmission systems, each offering unique benefits. For instance, belt-driven systems provide high operational efficiency for longer distances, whereas direct drives offer increased precision. Choosing the right type depends on the specific advantages applicable to your operational needs.

Comparative analysis of each system’s efficiency, cost, and maintenance requirements is necessary for making well-informed decisions. Balancing these factors leads to improved operational efficiency and reliability.

Making an Informed Decision

Making informed decisions involves a strategic approach to aligning system selection with operational goals. Considerations include:

- Assess System Requirements: Understand and evaluate what the system needs to accomplish.

- Review Product Specifications: Analyze the technical specifications of potential components.

- Supplier Reputation: Ensure the components come from reputable manufacturers.

- Cost Considerations: Budget constraints and cost-efficiency analyses.

- Maintenance Requirements: Consider ease of regular maintenance.

- Future Scalability: Potential for the system to support future growth.

By adhering to these considerations, businesses can enhance decision-making processes, ensuring optimal system functionality aligning with cutting tool selection guides.

Frequently Asked Questions

Power transmission efficiency relies on several factors including the quality of components, proper alignment, efficient lubrication, and the integration of modern technologies such as frequency drives. System layout and operational environment also play significant roles in determining efficiency.

Maintenance frequency varies based on system usage and environmental conditions. However, routine checks are recommended every three to six months to ensure optimal performance and early detection of potential issues. Regular upkeep prolongs system life and maintains efficiency.

Technologies such as variable frequency drives, IoT sensors, and condition monitoring systems help enhance efficiency by enabling better control and real-time analysis of system performance. Integrating these technologies can reduce energy consumption and increase reliability.

Essential tools for maintaining power transmission systems include basic hand tools for adjustments and repairs, as well as advanced monitoring equipment like thermal cameras and vibration analyzers for predictive maintenance. Proper tool selection is crucial for effective maintenance.